HotTapping-Machines.com

Free Tech Support on All Machines Sold For Life.

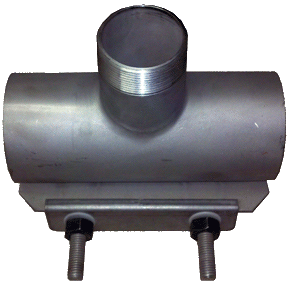

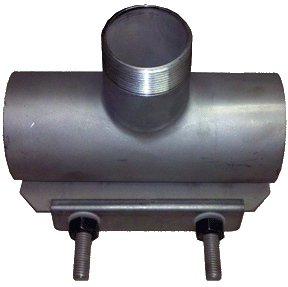

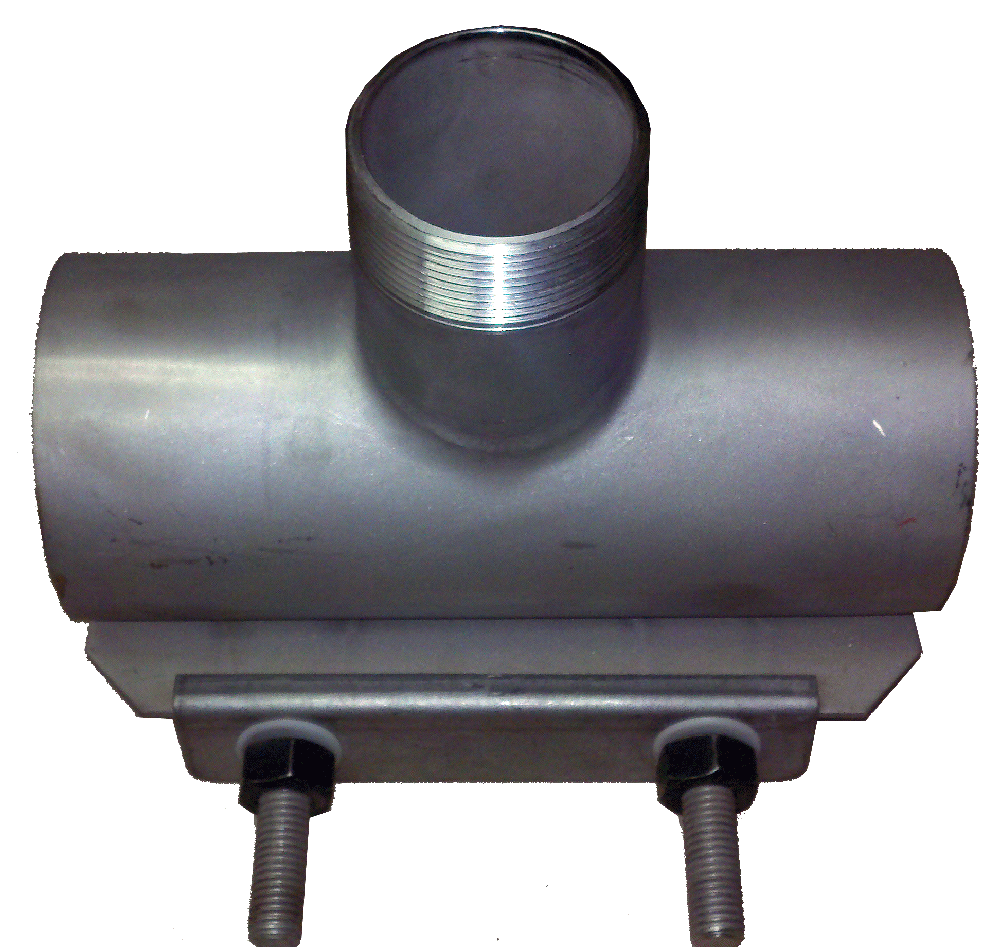

PVC-Steel Pipe Saddles/Sleeves

INSTALLATION INSTRUCTIONS FOR WATER WORKS TOOLS COPPER SADDLES

1. Thoroughly clean the pipe surface, and inspect the area where the saddle will be installed for flaws, gouges,

protrusions, excessive corrosion, etc. irregular surfaces should be avoided to assure maximum gasket sealing.

2. Lubricate the pipe and gaskets with a light soap/water solution and center the outlet of the saddle over the

desired area and continue around the pipe with the saddle.

3. Install washers, bars, flat Teflon washers and nuts. Evenly tighten the nuts and maintain and even gap

between the ends of the panel.

4. Tighten nuts evenly, alternating from one to the other always maintaining an even gap distance between both

panels. Tighten nuts in this sequence until tight. Do not over tighten. Wait 10-15 minutes to allow the gaskets to

fully compress. Recommended torque is 35-40 ft lbs.

5. Retighten nuts in sequence following step 4.

6. On Hot Water Lines, especially over 1300 -1400 F allow the gaskets to fully compress, and recheck the nut’s

tightness after 60-90 minutes. (After adding insulation, the heat to the gasket can increase, causing additional gasket compression.)